McCoy Torque Turn System – MTT™

FOR POWER TONGS

Leading-Edge Solutions for Optimal Performance

McCoy Global is transforming the industry with innovative technology solutions that enable our customers’ success, delivering optimal operational efficiency and performance, while keeping people, assets and the environment safe.

Innovation

Innovative system and software from a technology leader.

Expertise

20+ years of experience with thousands of torque monitoring systems in the field supporting customers’ needs.

Applications

- Monitor, control and analyze tubular connections make-up to ensure that all tubing and casing connections conform to manufacturer specifications

- MTT system monitors torque, turns and rotation speed of any power tong in real-time

The system uses MTT software that interacts with external control hardware and allows user to easily specify make-up parameters, control the process and evaluate quality of each connection make-up. Standard software features provide torque/turn graphs, generate customized reports and offer the ability to review results from previous make-ups for further analysis and information.

MTT System Components

MTT System hardware comes standard with:

- Display+ Ethernet Cable

- MTT Controller Unit

- Mini Junction Box with CT Cable

- Dump Valve Assembly with Dump Valve Cable

- Encoder with Encoder Cable

- Cables included are: encoder, dump valve, network and power cables

Features and Benefits

VTR Compatible

MTT software can support Virtual Thread Rep™ technology.

Technical Support

24/7 Technical Support is available as well as on site support.

Software Updates

Free MTT Software Updates are available on the VTR portal or by contacting McCoy Service Department.

Hardware Features and Benefits

- Non-hazardous location, safe area system is the standard option

- We also offer ATEX Zone 1 certified system with explosion-proof design that makes the system compliant for hazardous areas in all global regions, both on land and offshore

- Controller and PCs are separate to overcome the short lifecycle of PCs allowing the System to be in service much longer

- Controller with individual connections for easy direct sensor connections

- Improvement in Architecture: Flexible sensor configuration, wired or wireless ethernet communication, control electronics separate from computer housing

- Multiple sensor inputs allow for torque averaging / make / break operation from the same controller. No separate junction box needed

- Sensor/Cable Open Fault Detection, Output Short Protection

Software Features and Benefits

Standard

- Easy graphical report creation and “one step” PDF reporting system with customizable logo

- Automatic descriptive comments with user override

- Multiple joints review, graphic overlay

- Graph zooms to maximize size to computer screen

- Connection library - User customizable

- Automatic “Start Recording” and “Dump Valve Release”

- Adjustable Color Scheme

- Shoulder slope calculation

- User Mode – Administration and User Level 1 & 2 Access

Optional

Specialized

- Customizable components available on request

- Accept or reject connection on delta turn / shoulder slope

- RPM Graph can be added to make-up screen

- Control speed during make-up

- Custom zoom feature

- Pressure test system

- Multiple language capabilities

Virtual Thread Rep Technology Features

VTR STANDARD

is included with every MTT purchase (free of charge)

- Unlimited Cloud Based Data Storage of all Job Data

- Live Access to ‘active’ Jobs

- Access to all historical Jobs from any Location – online

- Access to Calibration info

- Fleet (Asset) Management

- Role Base Users access

- Online Connection Library

- MTT System Monitoring of Assets (on/off)

VTR PREMIUM

Is a Subscription to software that enables MTT system to perform additional functions, like:

- Remote control of LIVE job, including, but not limited to job editing, data interaction, hardware settings, communications to operator etc.

- Online Ability to setup jobs

- Ability to share LIVE Jobs and Completed Jobs to Other Organizations

- Key Metrics (Job stats for machine / fleet / operator) – derived from data

- Autonomous Evaluation of Graphs (Coming Soon)

Controller and System Specifications

Controller Specifications

- Sampling Rate: Base Rate 500 Samples/Second

- Torque Accuracy: Typically <0.5% Full Scale (not including Load Cell)

- Turns Accuracy: +/- 1 pulse of turns counter

- RPM Accuracy: Better than 0.25 RPM Error

- Pressure Accuracy: Typically <1%

- Response Time: Electronic Dump Valve

- Output Control: < 0.5 ms

- Hydraulic dump valve: typical 10 to 30 ms

- Approvals: iec 61010 – safety evaluated ce/lvd/emc/rohs/fcc.emc

- Power requirement: 100-240 V~, 50-60 Hz

- Power consumption: 1.4a max @ 100V~, 0.87a max @ 240V~

- Fcc – emc

- Rated temperature: -30°C +50°C, -22°F +122°F

- Altitude: 3048m

- Maximum humidity: 95% – non-condensing

- Protection: Nema 4, ip65

- Communication options: Wi-Fi 802.11 b/g or Bluetooth LE, ethernet 10/100

System Specifications

- Area Rating: General purpose

- Power Requirement: 100-240 V~, 0.87A MAX @240V~

- Rated Temperature: -30-50°C, -22-122°F

- Altitude: 3048M

- Maximum Humidity: 95% - non-condensing

- Protection: NEMA 4, IP65

- Controller Size: (366 mm x 311 mm x 125 mm),

(14.4” x 12.2” x 4.9”) - Controller Weight: 7.1 kg, 15.8 lbs

- Communication Options: WIFI 802.11 B/G, ethernet 10/100

APPROVALS:

- IEC 61010 – safety evaluated

- FCC – EMC

- CE 0 LVD/EMC/RoHS

Display Options and Specifications

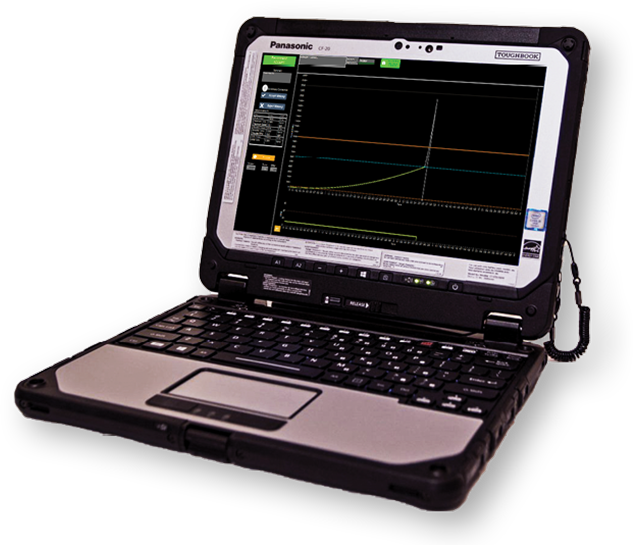

Toughbook

Innovative system and software specifically designed for use with hydraulic power tongs.

- Screen Size: 10.1”

- Intel Core i5 processor

- RAM: 8GB

- Hard Drive: 256GB

- Native Resolution: 1920 x 1200

- Monitor Features: Glove touch

- Webcam Capability

- Resolution (MP): 8 Megapixel (rear)

- Resolution: 1080p (front)

- Sunlight readable, Anti-glare, Anti-reflective

- WIFI

- Windows 10

- 4 USB ports

- Run Time, up to 8 hours on batteries with power supply built into the system

- Battery Packs are designed to be hot swapped

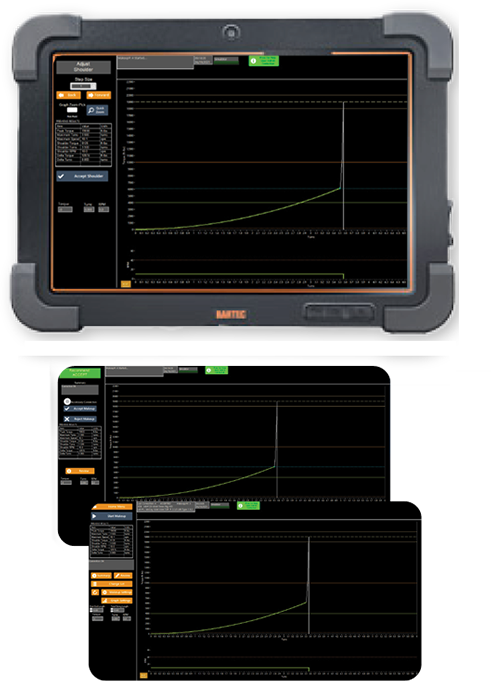

Tablet

ATEX certified when used with a tong and is non-ATEX when used with TTS sub, because of the RF modem (non-ATEX) that needs to be plugged in.

- Highly flexible industrial tablet PC with powerful Quad-Core processor for rough and hazardous environments

- Ergonomic positioned high quality 1D/2D imager SE4500 from Zebra and RFID reader HF/NFC

- Brilliant, high-resolution, bonded 10.1” touch LED display, sunlight readable, rain useable

- High quality 5 MP camera

- Integrated Bluetooth 4.1 LE, WLAN and optional LTE module

- Unique expansion port for customer specific applications

- Great number of accessories supporting productivity and operator safety

- Industry Tablet PC 10.1” for Zone 0 or Zone 1 / Div. 1

- Comes with a docking station and 2 spare batteries

- -20°C +50°C (-4°F +122°F) degree temperature range

- 1 USB port

- 1 Micro SD card that can be used as a backup

- Audio and microphone built-in

- Windows 10

- Screen Resolution:1920 x1200 with brightness of 700 nits

- Run Time, up to 8 hours on batteries with power supply built into the system

- Battery Packs are designed to be hot swapped so you have no downtime even when not docked

SmartEX Zone 1 ATEX Computer

ATEX certified when used with both, TTS sub and a tong, because it does not require an external modem.

- Industrial designed 12-inch LCD display

- Projected Capacitive Technology (PCT)

- Multi Touch, Glove Friendly

- Integrated RF Modem for direct communication to the TTS

- External USB type 2.0 port via ROTA DR4 connector

- Windows 10

- Operating Temp: -40°C to +60°C (-40°F to +140°F)

- Storage Temp: -40°C to +80°C (-40°F to +176°F)

- Screen Resolution: XGA 1024x768

- Weight < 33 lbs

- Ingress Protection: IP66 / NEMA4X

- ATEX Rating:

- II (2) GD Ex e mb ib [ib] IIC T4 Gb

- Ex tb IIIC T135°C Dc IP66

- Class I, Zone 1, AEx e ib mb [ib] IIC T4 Gb

- Class II, Zone 21 Ex tb [ibD]IIIC T135°C Db

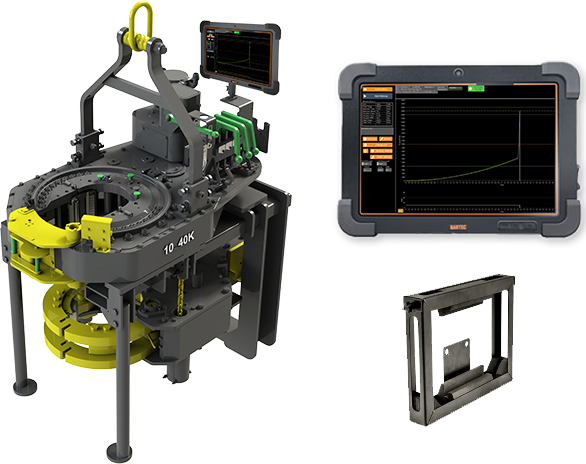

Tong Mounted Tablet Option

Functions

Enables the Operator to perform two functions:

- Operate the tong

- Monitor torque and turns during connection make-up

Display Mounting

- Tablet would slide in or out easily for battery changes

- Top would be hinged or fully removable

- If there is a closable top us thumb screws to release the top these would need to be captive

- Custom tablet holder may or may not have a closable top

- Off the shelf articulating mount in either permanent mount with screws, a clamp mount or a magnetic mount

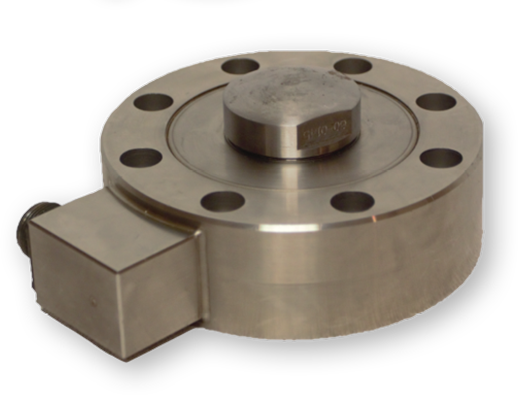

Load Cell Options

Part Number |

Type |

Form Factor |

Description |

|---|---|---|---|

MTT-OPT-470 |

Electronic |

Clevis Pin |

ASSEMBLY, Make Only, 6K |

MTT-OPT-471 |

Electronic |

Clevis Pin |

ASSEMBLY, Make Only, 10K |

MTT-OPT-472 |

Electronic |

Load Pin |

ASSEMBLY, Make Only, 25K |

MTT-OPT-473 |

Electronic |

Load Pin |

ASSEMBLY, Make Only, 25K, SIZE 50 |

MTT-OPT-474 |

Electronic |

Load Cell |

ASSEMBLY, Make Only, 30K, BUTTON COMPRESSION |

MTT-OPT-475 |

Electronic |

Load Pin |

ASSEMBLY, Make Only, 50K |

MTT-OPT-476 |

Electronic |

Load Cell |

ASSEMBLY, Make Only, 20K, PANCAKE (RoHS) |

MTT-OPT-477 |

Electronic |

Load Cell |

ASSEMBLY, Make Only, 30K, PANCAKE (RoHS) |

MTT-OPT-478 |

Electronic |

Load Cell |

ASSEMBLY, Make Only, 50K, PANCAKE (RoHS) |

MTT-OPT-479 |

Electronic |

Clevis Pin |

ASSEMBLY, Make/Break, 6K |

MTT-OPT-480 |

Electronic |

Clevis Pin |

ASSEMBLY, Make/Break, 10K |

MTT-OPT-481 |

Electronic |

Load Pin |

ASSEMBLY, Make/Break, 25K, SIZE 50 |

MTT-OPT-482 |

Electronic |

Load Pin |

ASSEMBLY, Make/Break, 25K |

MTT-OPT-483 |

Electronic |

Load Pin |

ASSEMBLY, Make/Break, 50K |

MTT-OPT-485 |

Electronic |

Load Cell |

ASSEMBLY, Make/Break, 30K, PANCAKE (RoHS) |

MTT-OPT-486 |

Electronic |

Load Cell |

ASSEMBLY, Make/Break, 30K, PANCAKE (RoHS) |

MTT-OPT-487 |

Electronic |

Load Pin |

ASSEMBLY, Make/Break, 50K, PANCAKE (RoHS) |

MTT-OPT-488 |

Electronic |

Load Pin |

ASSEMBLY, 50K, AVERAGING |

Part Number |

Type |

Form Factor |

Description |

|---|---|---|---|

MTT-OPT-407 |

Electronic |

Load Cell |

Assembly, 10k compression |

MTT-OPT-401 |

Electronic |

Load Cell |

Assembly, 20k compression |

MTT-OPT-402 |

Electronic |

Load Cell |

Assembly, 35k compression |

MTT-OPT-403 |

Electronic |

Load Cell |

Assembly, 15k compression |

MTT-OPT-406 |

Electronic |

Tension Link |

Assembly, 30k tension |

MTT-OPT-408 |

Electronic |

Tension Link |

Assembly, 10k tension |

MTT-OPT-409 |

Electronic |

Tension Link |

Assembly, 20k tension |

MTT-OPT-490 |

Hydraulic |

Tension Link |

Assembly, tension (4.08 sq in.)- 3k psi) |

MTT-OPT-497 |

Hydraulic |

Load Cell |

Assembly, compression (6.44 sq in.)- 3k psi) |

MTT-OPT-491 |

Hydraulic |

Tension Link |

Assembly, tension (6.53 sq in.)- 3k psi) |

MTT-OPT-492 |

Hydraulic |

Tension Link |

Assembly, tension (6.53 sq in.)- 3k psi) |

MTT-OPT-493 |

Hydraulic |

Tension Link |

Assembly, tension (10.8 sq in.)- 3k psi) |

MTT-OPT-494 |

Hydraulic |

Load Cell |

Assembly, compression (12 sq in.)- 3k psi) |

MTT-OPT-495 |

Hydraulic |

Load Cell |

Assembly, compression (16.1 sq in.)- 3k psi) |

MTT-OPT-496 |

Hydraulic |

Load Cell |

Assembly, compression (25.00 sq in.)- 3k psi) |

MTT-OPT-413 |

Hydraulic |

Tension Link |

Assembly, tension (4.08 sq in.)- 5k psi) |

MTT-OPT-414 |

Hydraulic |

Tension Link |

Assembly, tension (6.53 sq in.)- 5k psi) |

MTT-OPT-415 |

Hydraulic |

Tension Link |

Assembly, tension (10.8 sq in.)- 5k psi) |

Namur Proximity Sensors

Namur proximity sensors must be ATEX Zone 1 rated. The part numbers below are pre-approved for use with the ATEX MTT system.

Contact McCoy Global if other sensors are required.

MTT-OPT-370 ASSEMBLY, NAMUR 8MM, 3M Cable

MTT-OPT-402 ASSEMBLY, NAMUR 18MM, 3M Cable

Notes:

Load Cell is not included in the system.

A 30-foot cable is included with each load cell.

ELECTRONIC LOAD CELL OPTIONS 10 FT Cable (INCLUDED IN OPTION CODE) |

|---|

MTT-OPT-410 (ASSY, MTT, LOAD CELL, 30K, TENSION) |

MTT-OPT-411 (ASSY, MTT, LOAD CELL, 10K, TENSION) |

MTT-OPT-412 (ASSY, MTT, LOAD CELL, 20K, TENSION) |

MTT-OPT-440 (ASSY, MTT, LOAD CELL, 10K, PANCAKE) |

MTT-OPT-442 (ASSY, MTT, LOAD CELL, 15K, PANCAKE) |

MTT-OPT-441 (ASSY, MTT, LOAD CELL, 20K, PANCAKE) |

MTT-OPT-443 (ASSY, MTT, LOAD CELL, 35K, PANCAKE) |

HYDRAULIC LOAD CELL OPTIONS 10 FT Cable (INCLUDED IN OPTION CODE) |

|---|

MTT-OPT-490 (ASSY, MTT, TENSION (4.08 SQ IN.)- 3k PSI) |

MTT-OPT-497 (ASSY, MTT, COMPRESSION (6.44 SQ IN.)- 3k PSI) |

MTT-OPT-491 (ASSY, MTT, TENSION (6.53 SQ IN.)- 3k PSI) |

MTT-OPT-492 (ASSY, MTT,COMPRESSION (8.00 SQ IN.)- 3k PSI) |

MTT-OPT-493 (ASSY, MTT,TENSION (10.8 SQ IN.)- 3k PSI) |

MTT-OPT-494 (ASSY, MTT,COMPRESSION (12 SQ IN.)- 3k PSI) |

MTT-OPT-495 (ASSY, MTT,COMPRESSION (16.1 SQ IN.)- 3k PSI) |

MTT-OPT-496 (ASSY, MTT,COMPRESSION (25.00 SQ IN.)- 3k PSI) |

MTT-OPT-413 (ASSY, MTT, TENSION (4.08 SQ IN.)- 5k PSI) |

MTT-OPT-414 (ASSY, MTT, TENSION (6.53 SQ IN.)- 5k PSI) |

MTT-OPT-415 (ASSY, MTT,TENSION (10.8 SQ IN.)- 5k PSI) |