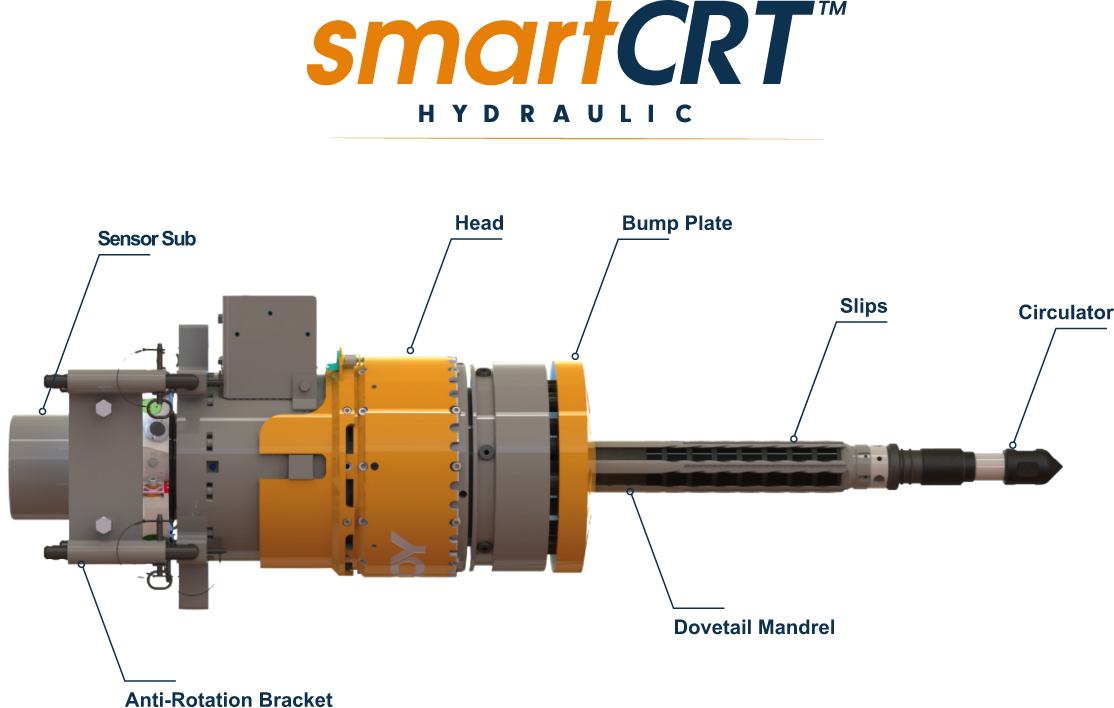

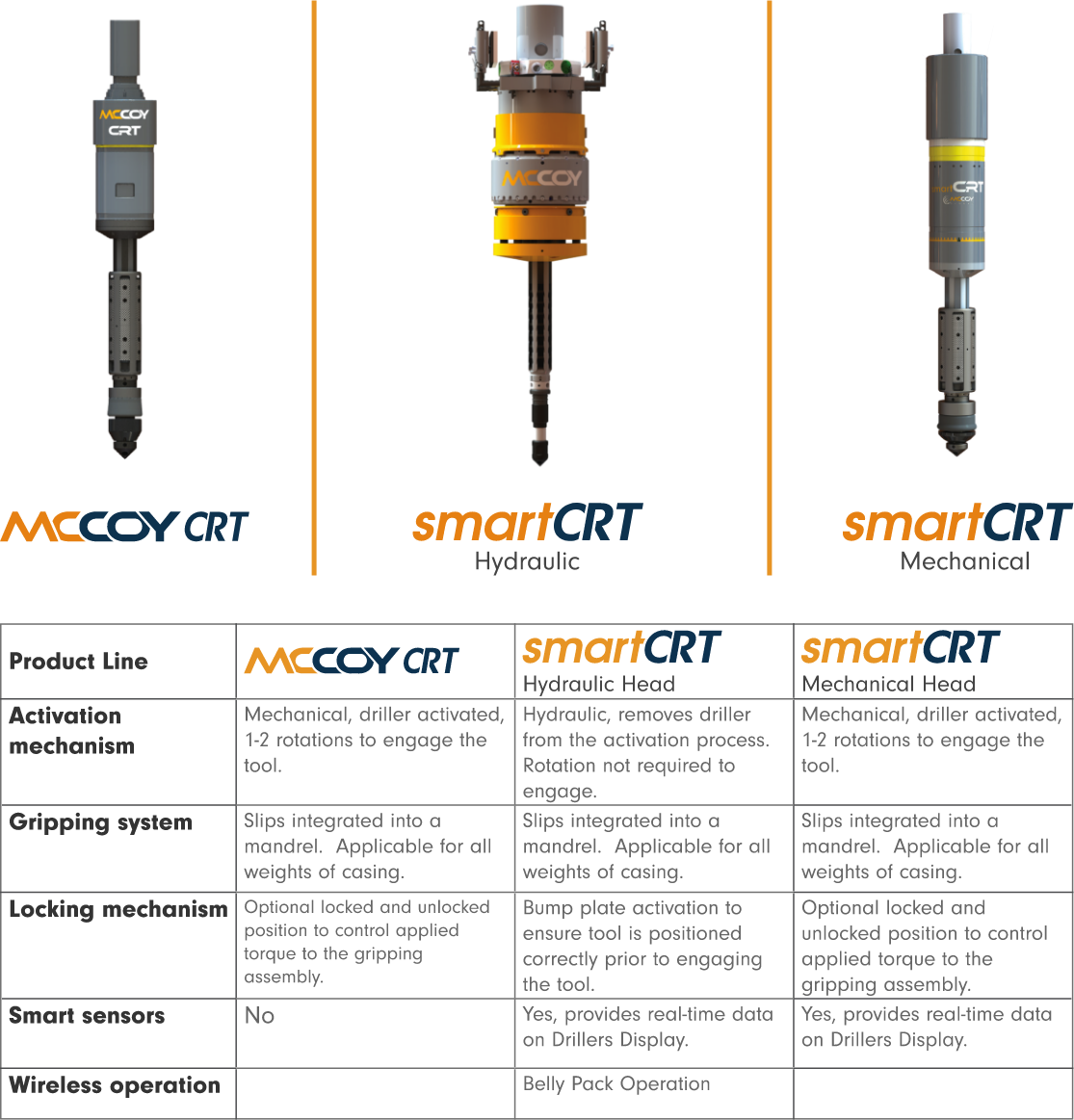

smartCRT™ Hydraulic

The smartCRT is an electronically integrated, game-changing casing running tool that streamlines operations while enhancing safety, efficiency, and repeatability. Its hydraulically operated, modular design enables seamless make-up, rotation, reciprocation, filling, circulation, and Casing while Drilling (CwD).

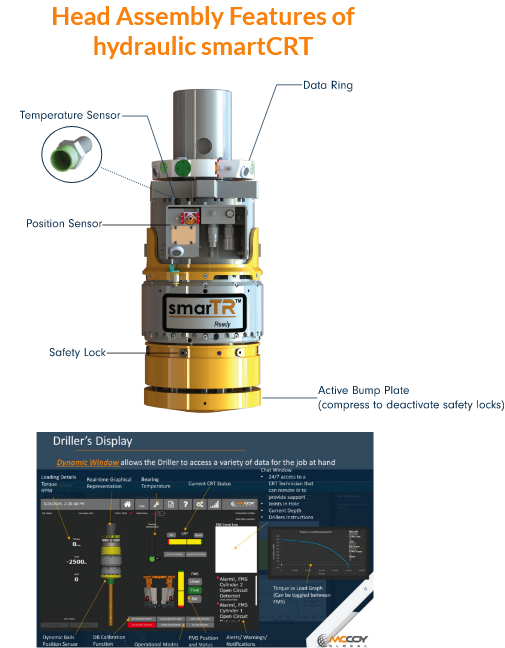

Fully “smarTR ready,” smartCRT incorporates wireless control and digital interaction through a driller’s display, providing clear and concise communication. The tool is equipped with a link tilt system, dynamic bails, and an optional remote belly pack for wireless operation, ensuring optimal safety and ease of use.

With its user-friendly design, low maintenance requirements, and versatile functionality, the smartCRT is the most adaptable and cost-effective CRT on the market, delivering unmatched performance and operational savings.

Technical Advantages of smartCRT

- Activation Process: Driller removal from activation, optimizing workflow and reducing operational complexity.

- Optimized Speed and Repeatability: Precision engineering enables higher throughput with consistent performance, improving cycle times and KPI performance.

- Wireless Remote Operation: Fully wireless control integration reduces the need for human presence in high-risk zones, enhancing operational safety in hazardous environments.

- Red Zone Mitigation: Remote operation reduces personnel exposure in “Red Zone” areas, meeting or exceeding industry safety standards for hazardous operations.

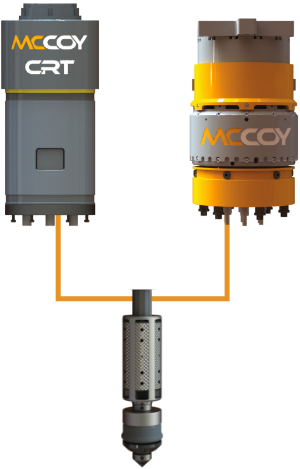

Modular Design smartCRT

NOTE: Hydraulic smartCRT and MCCOY CRT compatible accessories:

• Dovetail Mandrel

• Base Slips

• Wear Guides

• Inserts

• Circulator Assembly

NOTE: smartCRT’s Hydraulic Head and Mechanical Head compatible accessories:

• Wear Guides

• Inserts

• Circulator Assembly

*Mandrels and Base Slips are not compatible.

Key Benefits of smartCRT:

- Safety: Enhances rig site performance while reducing manpower requirements and Total Recordable Incident Rate (TRIR), creating a safer work environment.

- Integration: “Clear the Floor” by combining hardware and software for remote operational control. Seamless digital interaction through smarTR allows for more efficient and safer operations.

- Interchangeability: Enables operators to switch between hydraulic and

mechanical without requiring additional equipment, providing enhanced operational flexibility and adaptability. - Repeatability: Streamlines operations to increase joints per hour (JPH) and reduce non-productive time (NPT), ensuring consistent performance and maintaining a safe working environment.

- Cost Efficiency: The use of a common assembly across various tools reduces inventory costs and simplifies maintenance, contributing to overall cost savings.

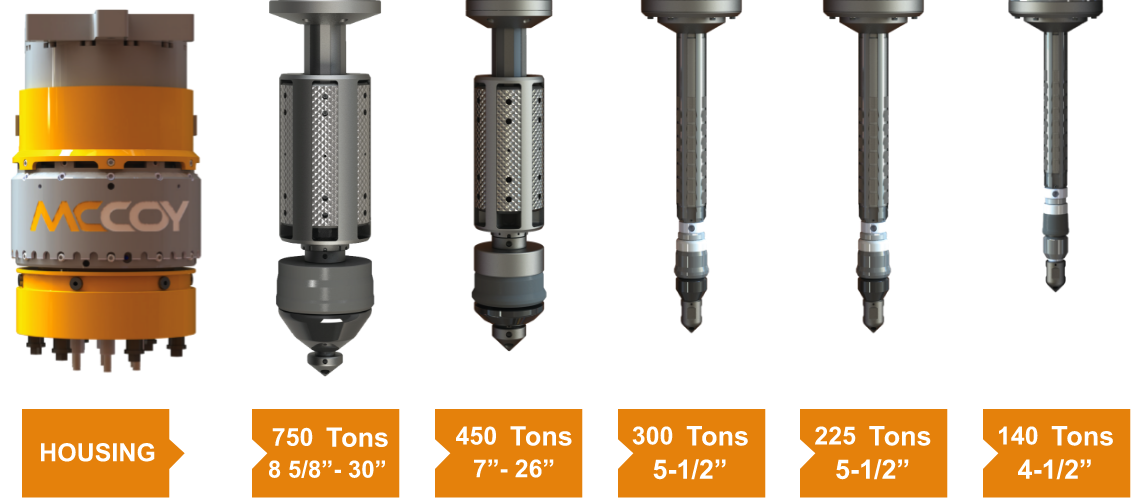

450 Ton Compatibility:

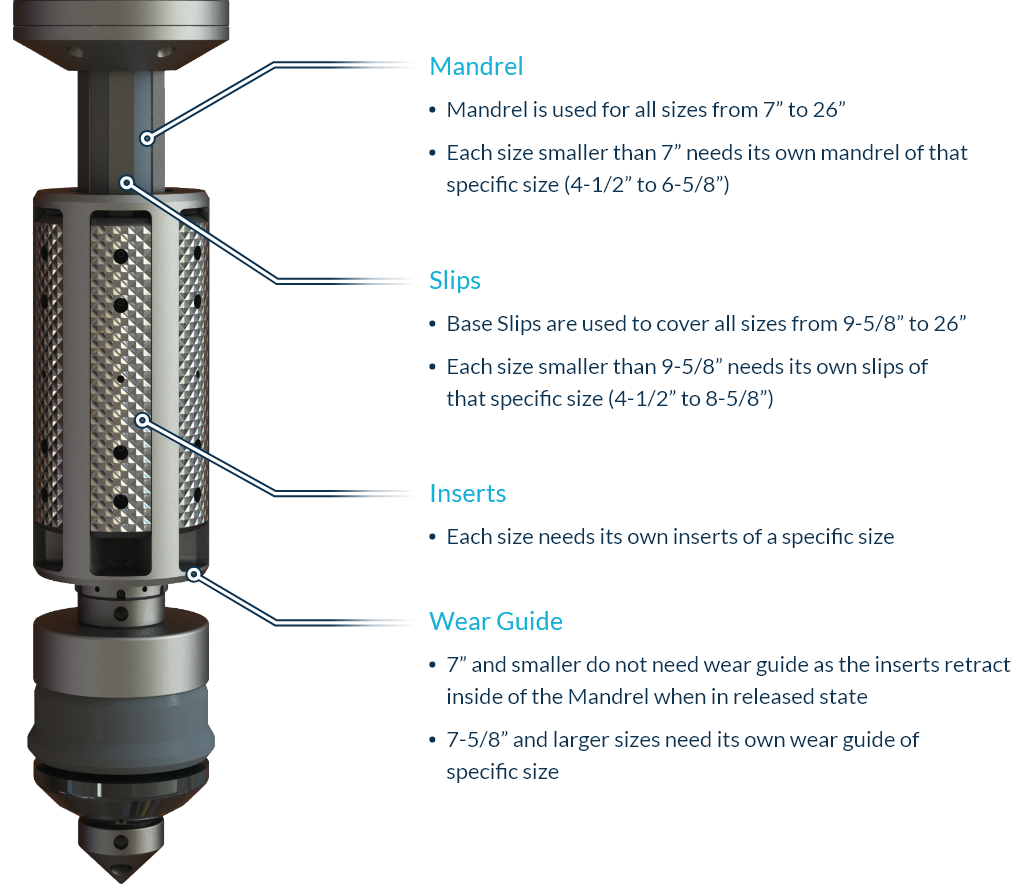

The hydraulic smartCRT is fully compatible with 450-ton mandrels and accessories, offering unparalleled asset utilization across various application use cases. This compatibility allows end-users to customize the tool to meet specific operational needs without incurring the costs associated with multiple tools.

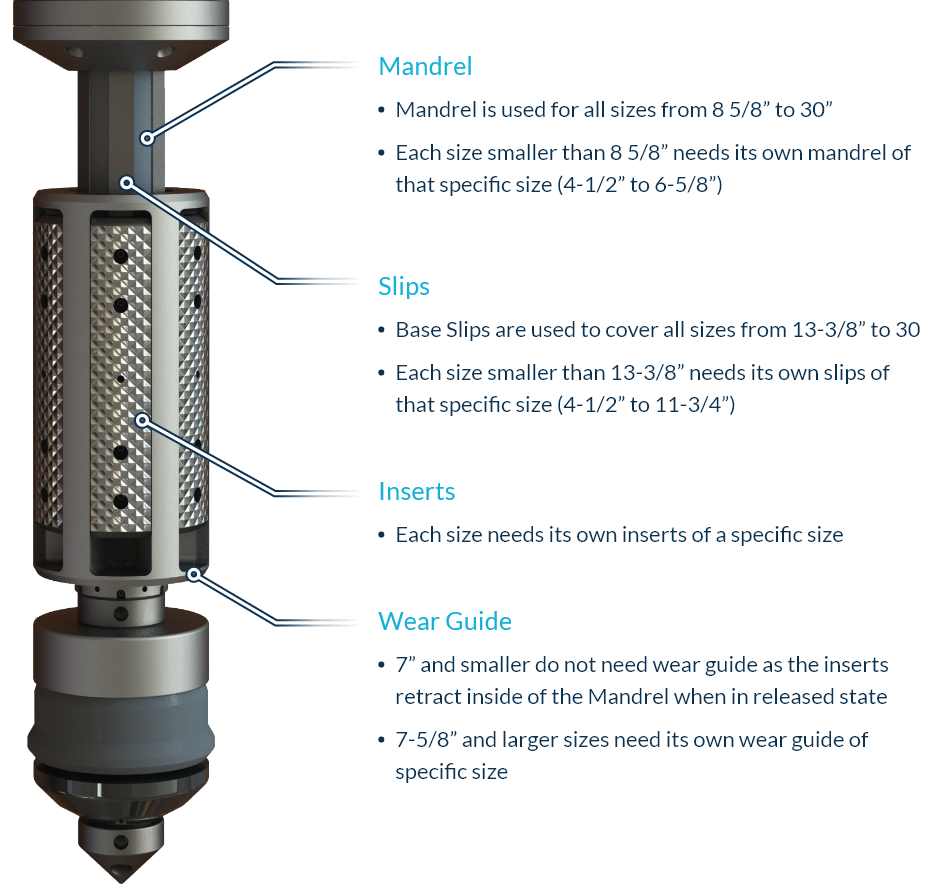

750 Ton Compatibility:

The hydraulic smartCRT uses the same inserts, wear guides and circulators as the mechanical smartCRT tool.

The ability to handle a wide range of mandrels (4.5” to 30”) with just one tool has several benefits:

- A larger range of casing sizes can be accommodated

- Significant inventory and spare parts costs are reduced

- Minimal cost for additional sizes added to a fleet