GAGING (GAUGING) SERVICES

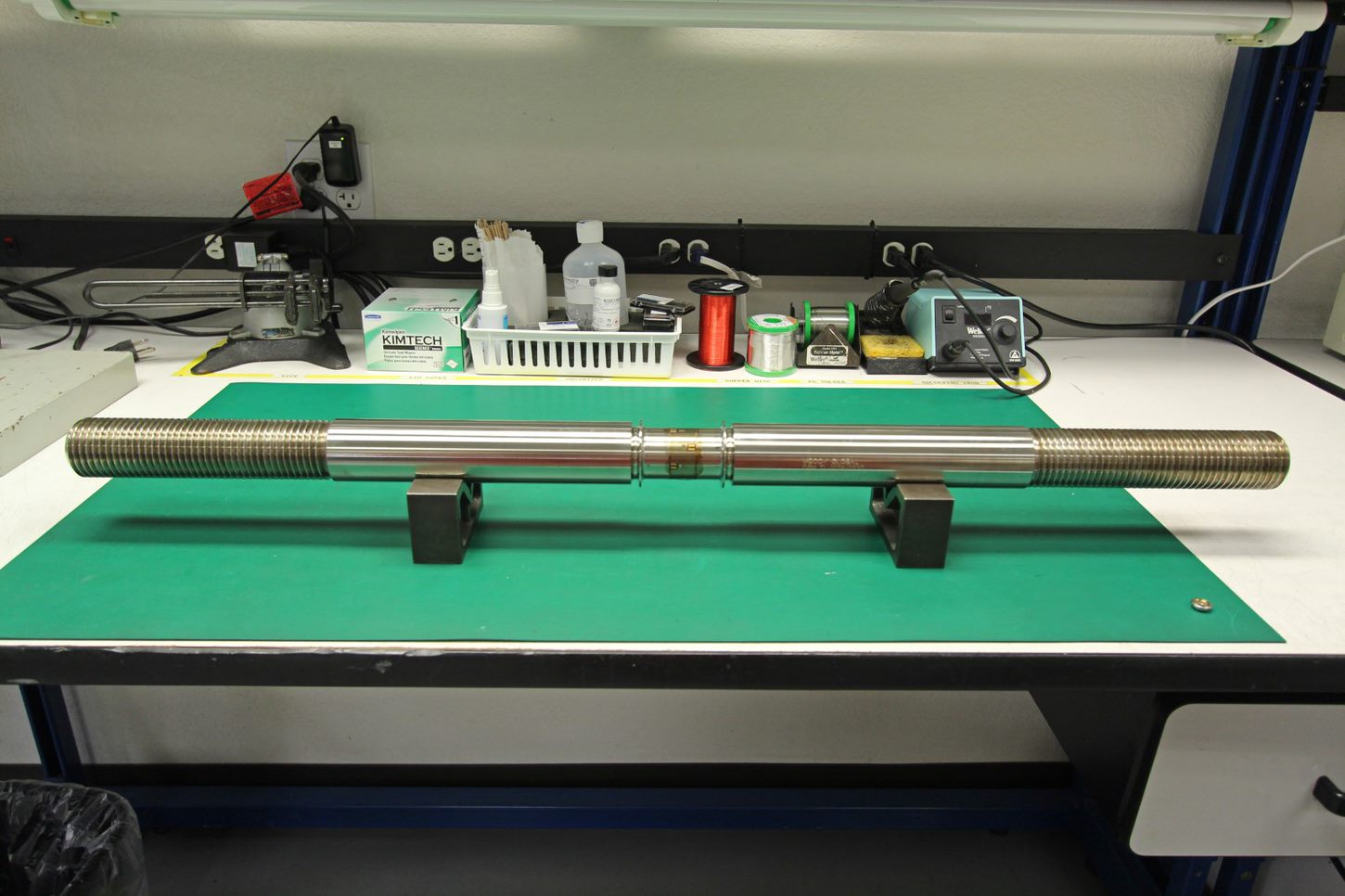

McCoy Global offers strain gage (gauge) installation services for those customers who do not have the capability or capacity to perform the strain gage bonding process. Strain gages can be installed on many products and components to verify finite element models, measure static and dynamic forces or to create custom load transducers.

We are an ISO 9001 company with a highly skilled team of engineers and technicians with over 30 years’ of strain gauge application, testing, and calibration experience in producing strain gage based load cells. Our engineers can help you identify the type of strain gages and bonding material needed for your application and determine the best location to bond the strain gages on your part. We specialize in bonding strain gages in difficult locations which are subjected to extreme environmental conditions. Some of the materials that we have bonded strain gages to include: steel, aluminum, carbon fiber, plastics, and titanium.

Our Capabilities Include:

- Full Turnkey solutions with in house design services available

- Modify Existing Components

- Gaging Only Solutions

- Customer Gage Carrier design and construction

- Bonding on inside bore, blind holes, pockets, diaphragms and other customer needs.

- No Minimum Quantity required

- Strain gage installations are temperature compensated on-site and can be zero balanced after the wiring and testing is completed.

- McCoy Global also has the on-site capability to perform NIST traceable calibrations up to 4 million pounds, Torque to 150K ft-lbs, Pressure to 15 kpsi.

- Other load calibrations include: Bending and Lateral Shear.

- Strain gage installations can be performed on equipment or components at the customer's facility.

- Environmentally controlled gauging laboratory separated from main production area.

- Experience with a wide range of strain gauges and bonding adhesives. Includes: high temperature, high cycle, harsh environment.

- Services include bridge completion and testing for calibrated load measurement, and gauging for structural stress analysis.

- Production facility includes multiple large capacity gauge curing ovens, multiple large capacity thermal testing/compensation chambers.

- All load testing and environmental compensation testing has automated data collection with traceability to NIST.

- Engineering application support includes: CAD, Solid Modeling, FEA

Our Gaging Application Environments Expertise

- Underwater devices, Marine and shipboard

- Automotive and Aerospace

- Mobile and overhead crane applications

- Down Hole Tools for Oil and Gas Industry

- Instrumentation